FiberJet Blown Fiber 2~12 Core

Fiberjet Blown Fiber from VisionTek Fiber Optic System

Fiber Optic System»Fiberjet Blown Fiber»FiberJet Blown Fiber 2~12 Core (Back)

FiberJet Blown Fiber 2~12 Core

FiberJet Blown Fiber 2~12 Core

Features and Benefits:

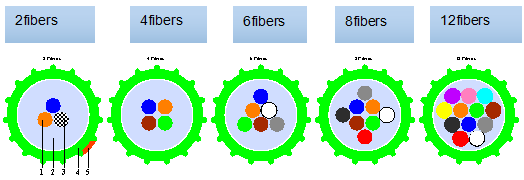

● 2、4、6、8 and 12 fibers options.

● Stable structure, good mechanical and temperature performance.

● Designed with special grooves to advance blowing distance.

● Lightweight and proper stiffness, repeat installation.

● Designed with no gel, easy

● Better costs advantage compared

● Complete accessories, less manpower, lower installation time.

Standards:

Unless otherwise specified in this specification, all requirements shall be mainly in accordance with the following standard specifications.

● Optical fiber ...ITU-T G.651、G.652、G.655、G.657 IEC 60793-2-10、IEC 60793-2-50

● Optical Cable

Note: It is recommended that the structure of 2 fibers unit consist of 2 filled fibers, for it is proved that this structure is better in the blowing performance and the fiber separability than that of one with zero or one filled fiber

Technical Parameter

Fiber Unit Structure

1. Optical fiber 2. Resin 3. +1 'Filled' fiber 4. Low Friction Sheath 5. Groove

Basic Performance:

|

Fiber Count |

2 fibers |

4 fibers |

6 fibers |

8 fibers |

12 fibers |

|

Outer Diameter (mm) |

1.15±0.05 |

1.15±0.05 |

1.35±0.05 |

1.50±0.05 |

1.65±0.05 |

|

Weight (g/m) |

1.0 |

1.0 |

1.3 |

1.8 |

2.2 |

|

Min Bend radius (mm) |

50 |

50 |

60 |

80 |

80 |

|

Temperature |

Storage: -30℃ ~ +60℃ Operation: -20℃ ~ +60℃ Installation: -5℃ ~ +50℃ |

||||

Testing parameter

Fiber Unit Attenuation:

|

Fiber Type |

SM G.652D、G.655、G.657 |

MM 62.5/125 |

|

Attenuation |

0.38dB/km max @1310nm |

3.5dB/km max @850nm |

Blowing Test:

|

Fiber Count |

2 fiber s |

4 fiber s |

6 fiber s |

8 fiber s |

12 fiber s |

|

|

Test equipment |

PLUMETTAZ:UM25, ERICSSON:F, CATWAY:FBT-1.1 |

|||||

|

Standard duct |

5.0/3.5 mm |

|||||

|

Pressure |

7bar / 10bar |

|||||

|

Typical blowing distance |

500m / 1000 m |

500m / 1000m |

500m / 1000m |

500m / 1000m |

500m / 800m |

|

|

Blowing time |

10 min / 18 min |

10 min / 18 min |

12 min / 18 min |

13 min / 18 min |

15 min / 20 min |

|

Mechanical Performance:

|

Test |

Standard |

Parameters |

Test Results |

|

Tension |

IEC 60794-1-2-E1 |

Load is 1×W |

fiber strain ≤0.4% at MAX |

|

Bend |

IEC 60794-1-2-E11A |

Diam 40mm×3turns |

Additional attenuation ≤0.05dB,after test |

|

Crush |

IEC 60794-1-2-E3 |

100 N, 60s |

Additional attenuation ≤0.05dB,after test |

|

All optical testing proceeded at 1550 nm |

|||

Environment Performance:

|

Test |

Standard |

Parameters |

Test Results |

|

Temperature Cycle |

IEC 60794-1-2-F1 |

+20℃, -40℃, +60℃, |

Absolute attenuation ≤0.5dB/km,during test |

|

Water Soak |

IEC 60794-5 |

1000 hours in water, |

(Test after temp cycle) ≤0.07dB/km |

|

Damp Heat Cycle |

IEC 60068-2-38 |

25℃, 65℃, |

Absolute attenuation ≤0.5dB/km,during test |

|

All optical testing proceeded at 1550 nm |

|||

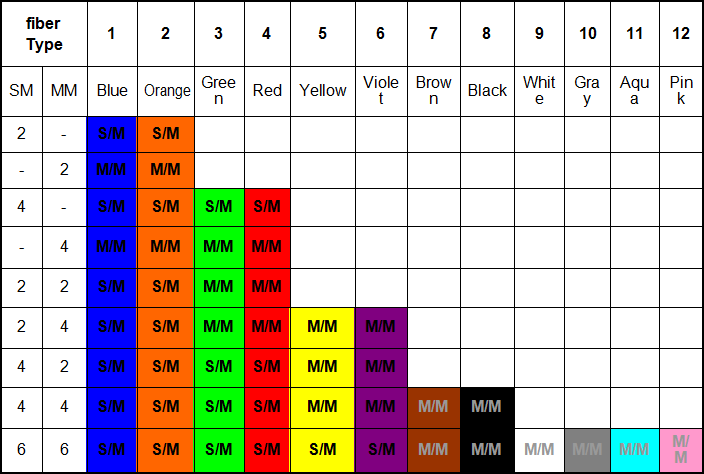

Ordering Information

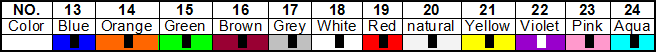

Fiber Color Code ( fiber colors can also be determined by customer )

Sheath Color:

Standard delivery lengths are 1000m, 2000m, 4000m, 6000m with a tolerance of -0.5~+1%.

For more options, please contact the customer service.

Packaging:

Free coiling in the pan.

Super Mini blown cable ( 2~24cores )

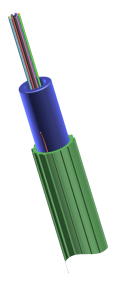

Introduction:VisionTek began to research air blown cable since 2009. Now, it can produce various types of air blown cable. Its main product is central tube air blown cable and layer stranding air blow cable which has

Standards:

Unless otherwise specified in this specification, all requirements shall be mainly in accordance with the following standard specifications.

Optical fibers ....................................ITU-T G.652D

Optical fibers ....................................IEC 60793 B1.3

Cables ..........................................IEC 60794

The structure of cable:

|

1. Optical Fiber |

2. Jelly |

3. Groove |

|

4. Ripcord |

5. Loose Tube |

6. HDPE Sheath |

Technical Index:

|

Cable Type |

Central Loose Tube Cable |

||||

|

Fibers Count |

2~4 |

6~8 |

12 |

24 |

|

|

Thickness of HDPE sheath |

Nominal value:0.20mm, Average value:0.15mm |

||||

|

Nominal Overall Diameter |

2.0±0.1mm |

2.3±0.1mm |

2.5±0.1mm |

2.8±0.1mm |

|

|

Weight |

4.0 kg/km |

5.0 kg/km |

5.5 kg/km |

7.5 kg/km |

|

|

Max. Tensile Strength |

80N |

80N |

80N |

100N |

|

|

Max. Crushing force |

600N/100mm |

||||

|

Min. Bending radius -Static |

10 outer Φ |

||||

|

Min. Bending radius -Dynamic |

20 outer Φ |

||||

|

Temperature |

Storage |

-20~+50℃ |

|||

|

|

Installation |

-10~+40℃ |

|||

|

|

Operation |

-20~+50℃ |

|||

Testing Index Blowing performance:

|

Blowing Tool |

Typical blowing length |

||

|

PLUMETTAZ:PR-140, MiniJet-400 etc. |

Fibres Count |

Duct type |

Duct type |

|

24 fibres |

200~500m |

1000m |

|

Mechanic performance:

|

Item |

Testing Method |

Testing Results |

Specified Value |

|

|

Tension performance

|

IEC 60794-1-2-E1

|

Optical fibre strain |

Additional attenuation |

Max. Tensile Strength =

|

|

Short term: ≤0.3% |

Short term:

|

|||

|

Crush |

IEC 60794-1-2-E3 |

Short term:

|

Short term |

|

|

Repeated bending |

IEC 60794-1-2-E6 |

After test,

|

R=20 outer Φ |

|

|

Bending load =15N |

||||

|

Bending times =25 |

||||

|

Torsion |

IEC 60794-1-2-E7 |

After test,

|

Torsion angle=±180� |

|

|

Torsion load =15N |

||||

|

Torsion times =5 |

||||

|

Cable bend |

IEC 60794-1-2-E11A |

After test, The optical fibre can't be broken; |

R=20 outer Φ |

|

|

All optical testing proceeded at 1550 nm |

||||

Environment performance:

|

Item |

Testing Method |

Testing Results |

||

|

Temperature cycling |

IEC 60794-1-2-F1 |

Allowable additional attenuation (1550nm) |

||

|

G.652B |

G.652D |

G.655 |

||

|

|

||||

|

Water penetration |

Water column: 1m, 1m cable, Period:24 hours |

No water leak through the open end of cable |

||

|

Filling compound flow |

70℃, Period:24 hours |

No compound flow from the cable |

||

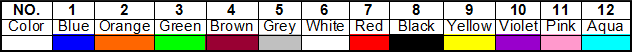

Other Index Fiber Colors:

with black ring marks in 100mm intervals

Delivery Lengths:

Standard delivery lengths are 2km, 4km, 6km with a tolerance of -1%~+3%.

|

Fiber Count |

Drum length |

Drum Size |

Packing Size |

Net/Gross Weight |

|

2~12 Fibers |

2000 |

Φ600×460 |

640×640×460 |

10.0/30.0 |

|

4000 |

Φ600×460 |

640×640×460 |

20.0/40.0 |

|

|

6000 |

Φ600×460 |

640×640×460 |

30.0/50.0 |

|

|

24 Fibers |

2000 |

Φ690×450 |

855×670×450 |

15.0/35.0 |

|

4000 |

Φ710×450 |

875×690×450 |

30.0/50.0 |

|

|

6000 |

Φ730×570 |

895×710×570 |

45.0/70.0 |

<0.1 dB,

<0.1 dB,